Goods Receipt is the process of recording the receipt of products or materials into inventory after delivery. It ensures accurate tracking of stock levels and verifies that the received goods match the purchase order specifications. This process is essential for maintaining inventory accuracy and enabling timely payment to suppliers.

Goods receipt process in warehouse management

The goods receipt process in warehouse management involves verifying and recording incoming shipments to ensure accuracy and quality. This crucial step helps maintain inventory integrity and supports efficient stock control. Proper execution of this process enhances supply chain reliability and reduces errors.

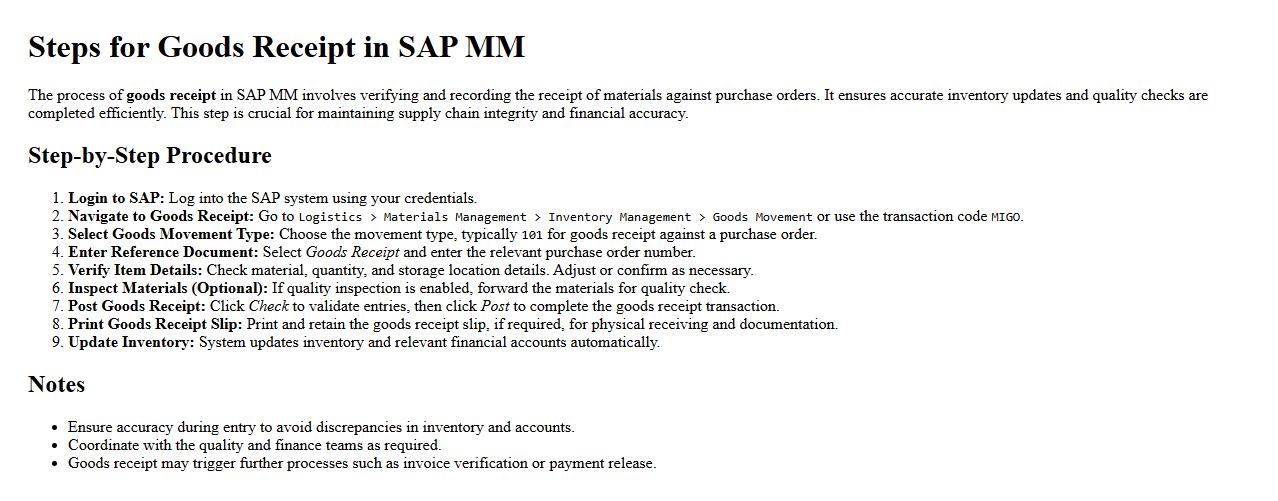

Steps for goods receipt in SAP MM

The process of goods receipt in SAP MM involves verifying and recording the receipt of materials against purchase orders. It ensures accurate inventory updates and quality checks are completed efficiently. This step is crucial for maintaining supply chain integrity and financial accuracy.

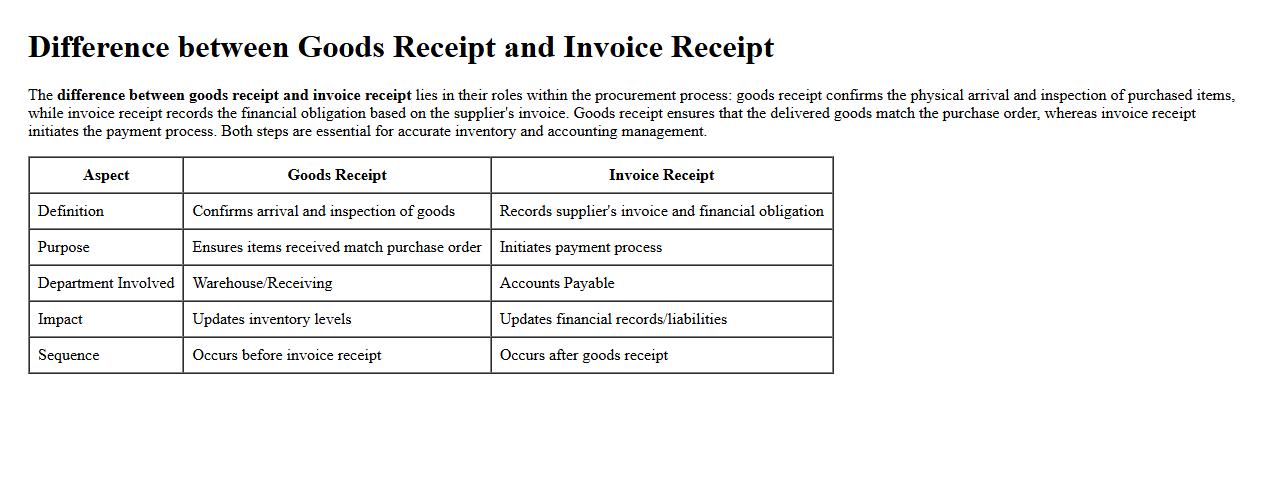

Difference between goods receipt and invoice receipt

The difference between goods receipt and invoice receipt lies in their roles within the procurement process: goods receipt confirms the physical arrival and inspection of purchased items, while invoice receipt records the financial obligation based on the supplier's invoice. Goods receipt ensures that the delivered goods match the purchase order, whereas invoice receipt initiates the payment process. Both steps are essential for accurate inventory and accounting management.

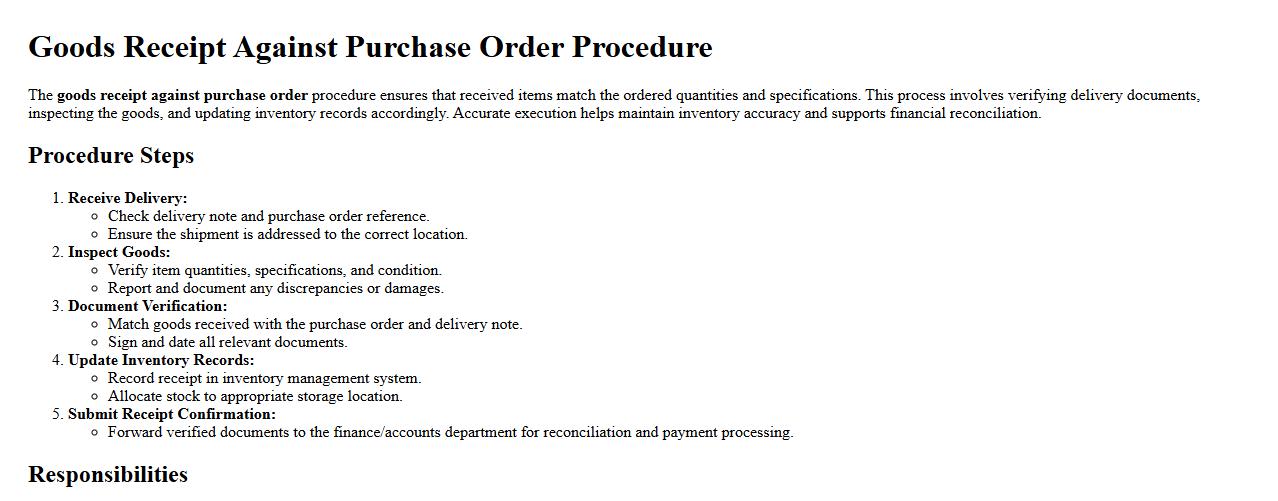

Goods receipt against purchase order procedure

The goods receipt against purchase order procedure ensures that received items match the ordered quantities and specifications. This process involves verifying delivery documents, inspecting the goods, and updating inventory records accordingly. Accurate execution helps maintain inventory accuracy and supports financial reconciliation.

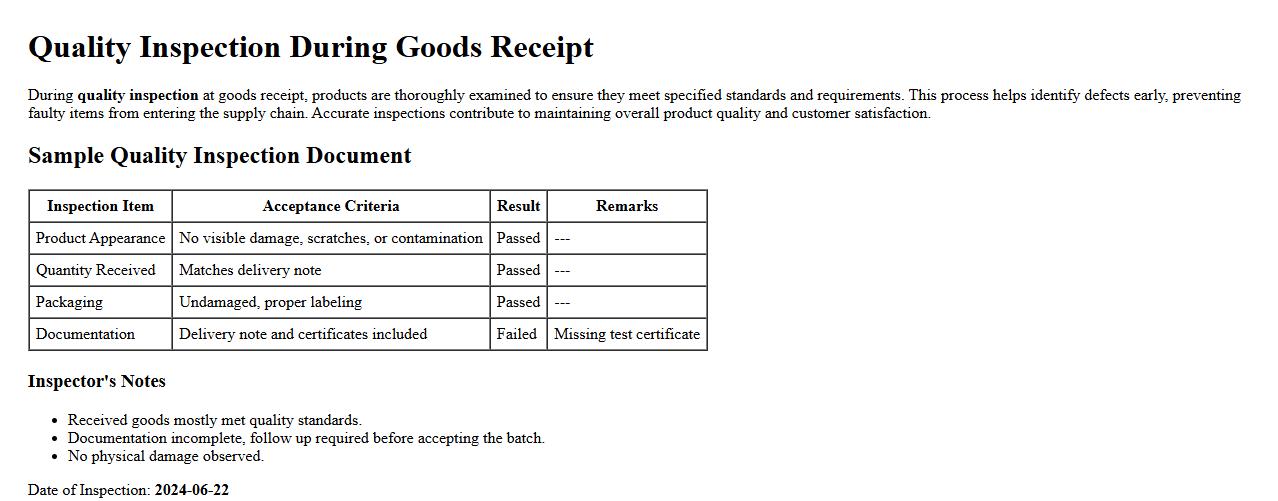

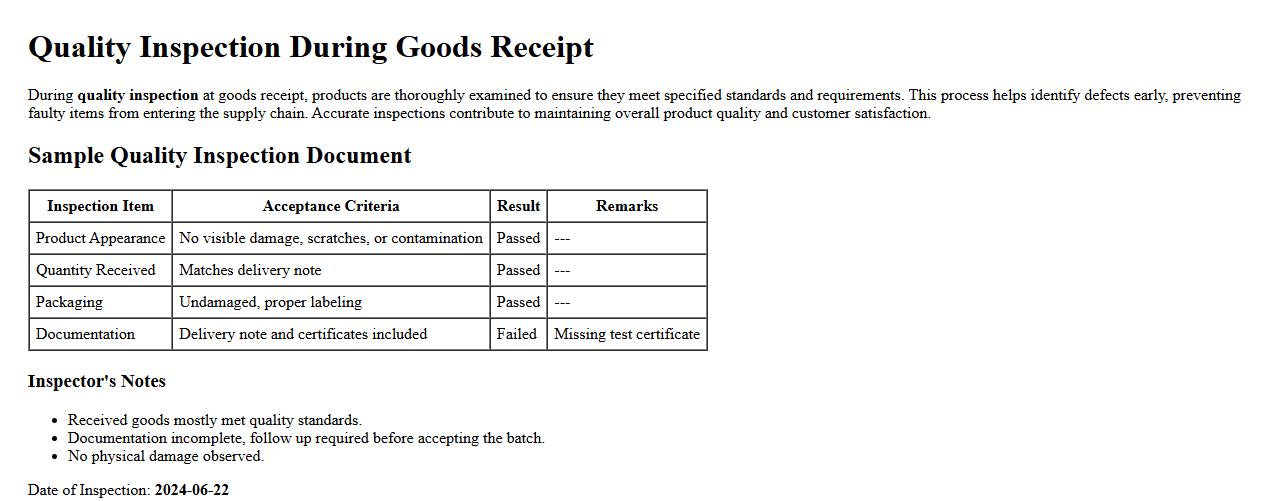

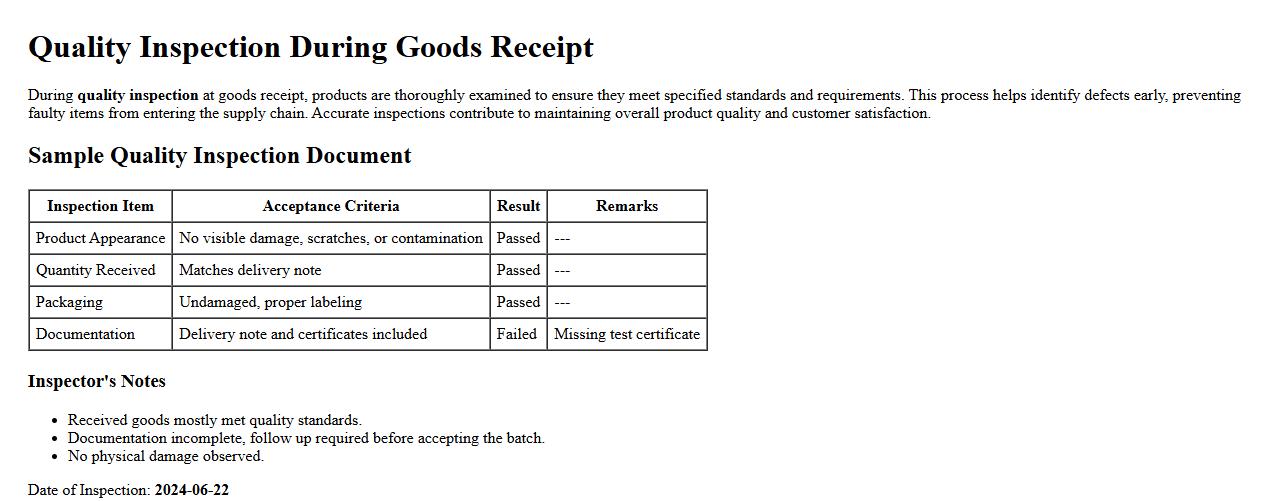

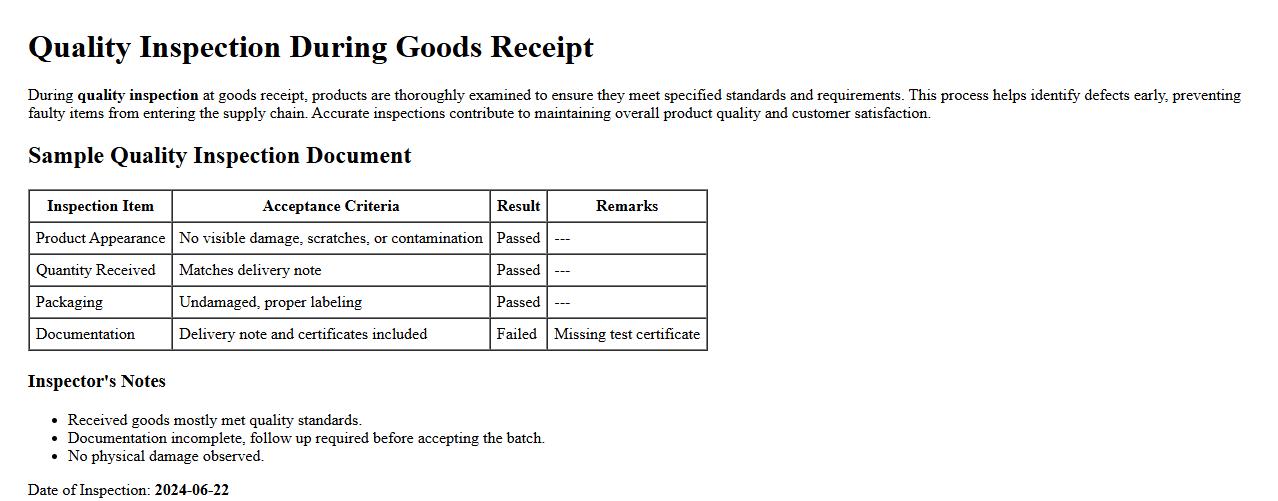

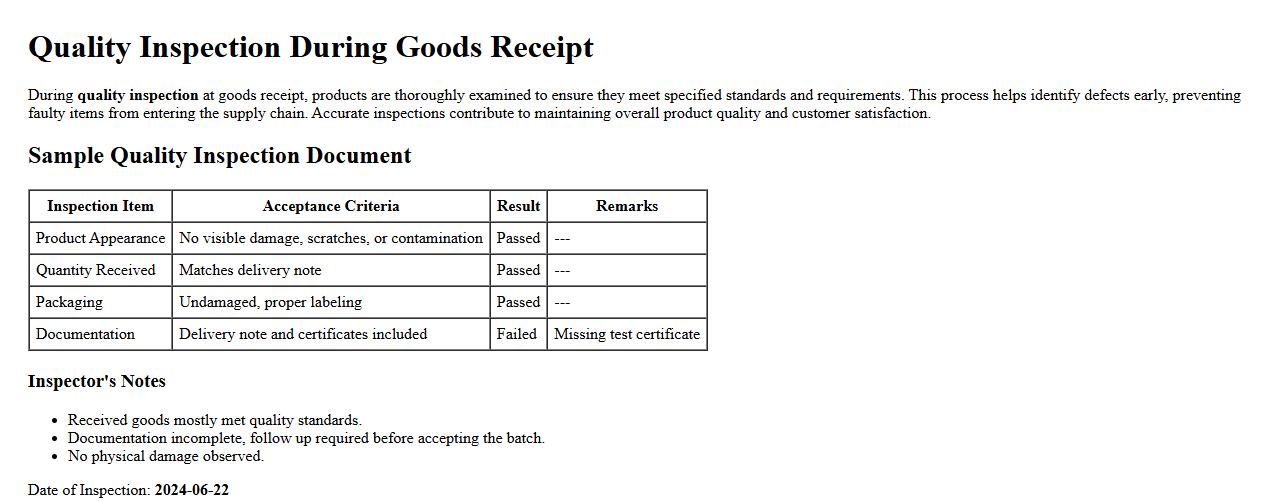

Quality inspection during goods receipt

During quality inspection at goods receipt, products are thoroughly examined to ensure they meet specified standards and requirements. This process helps identify defects early, preventing faulty items from entering the supply chain. Accurate inspections contribute to maintaining overall product quality and customer satisfaction.

Manual versus automatic goods receipt entry

The process of manual versus automatic goods receipt entry significantly impacts inventory management efficiency. Manual entry involves human input, which may lead to errors and slower processing times, whereas automatic entry utilizes technology for faster, more accurate data capture. Choosing the right method enhances operational accuracy and streamlines supply chain workflows.

Common errors in goods receipt processing

Understanding common errors in goods receipt processing is essential for maintaining accurate inventory records and ensuring smooth supply chain operations. These errors often include incorrect quantities, damaged goods, and mismatched documentation. Addressing these issues promptly helps prevent delays and financial discrepancies in the procurement process.

Documentation required for goods receipt

The documentation required for goods receipt ensures accurate verification and tracking of incoming shipments. It typically includes purchase orders, delivery notes, and inspection reports. Proper documentation is essential for maintaining inventory accuracy and facilitating smooth supply chain operations.

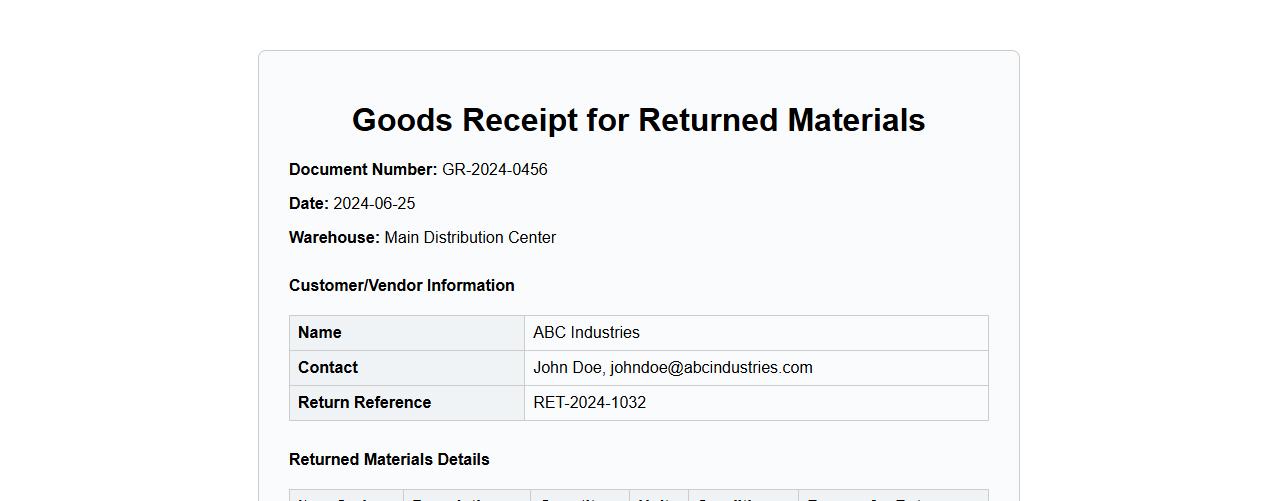

Goods receipt for returned materials

A goods receipt for returned materials documents the process of accepting items back into inventory after they have been returned by customers or vendors. This ensures accurate tracking and updating of stock levels. Proper recording helps maintain inventory integrity and supports efficient supply chain management.

Best practices for efficient goods receipt

Implementing best practices for efficient goods receipt ensures accurate inventory management and reduces processing time. Key steps include verifying shipment contents against purchase orders, promptly recording received goods, and maintaining clear communication with suppliers. These practices enhance overall operational efficiency and minimize errors in the supply chain.

How to verify item discrepancies on a Goods Receipt document?

To verify item discrepancies on a Goods Receipt document, compare the received quantities against the purchase order. Check for any variances in product description, batch numbers, and condition. Document any differences to initiate corrective actions or supplier claims.

What key details are mandatory on a Goods Receipt note?

A Goods Receipt note must include the purchase order number, received quantities, and date of receipt. It should also contain supplier information and item descriptions. These details ensure accurate inventory updates and audit trail compliance.

How is a Goods Receipt used in three-way matching?

In three-way matching, the Goods Receipt is compared with the purchase order and the supplier invoice. This process confirms that the ordered, received, and billed quantities align. It helps prevent payment errors and ensures proper financial control.

Which authorization levels are required for Goods Receipt approval?

Goods Receipt approval typically requires authorization from the inventory manager, procurement officer, and sometimes the finance department. Each level verifies the accuracy and legitimacy of the receipt. This multi-level approval mitigates risk of fraud and errors.

What common errors occur during Goods Receipt data entry?

Common errors include incorrect quantity entry, wrong item codes, and missing purchase order references. Such mistakes can cause inventory discrepancies and payment delays. Implementing validation checks reduces these data entry errors significantly.