The Equipment Maintenance Record Form Sample is a practical template designed to track and document the routine servicing and repairs of machinery or equipment. This form helps ensure consistent maintenance schedules, captures essential details such as service dates, performed tasks, and technician notes. Utilizing such a record supports prolonging equipment lifespan and minimizing downtime by identifying potential issues early.

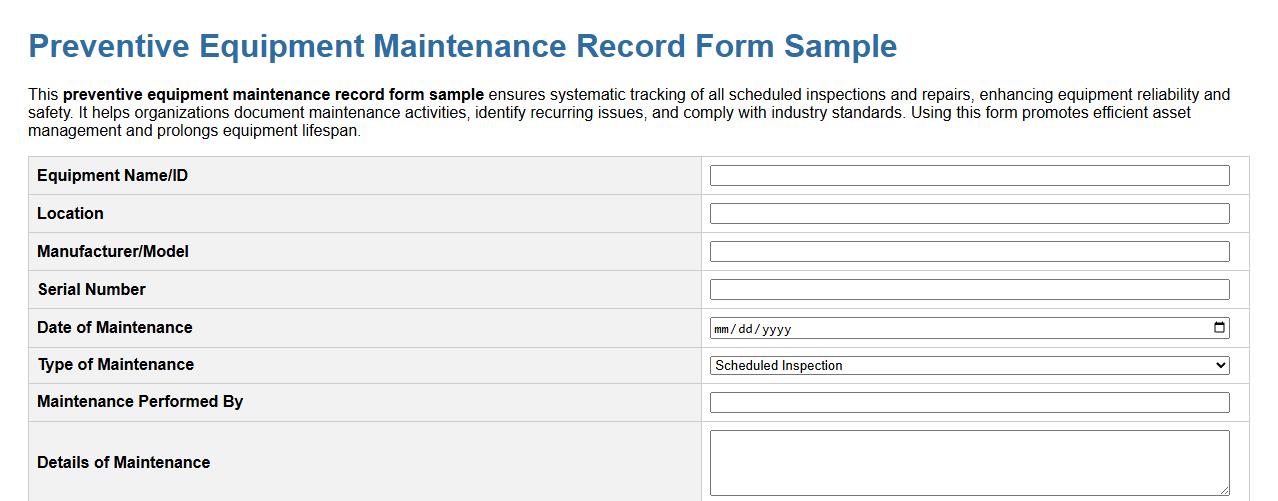

Preventive equipment maintenance record form sample

This preventive equipment maintenance record form sample ensures systematic tracking of all scheduled inspections and repairs, enhancing equipment reliability and safety. It helps organizations document maintenance activities, identify recurring issues, and comply with industry standards. Using this form promotes efficient asset management and prolongs equipment lifespan.

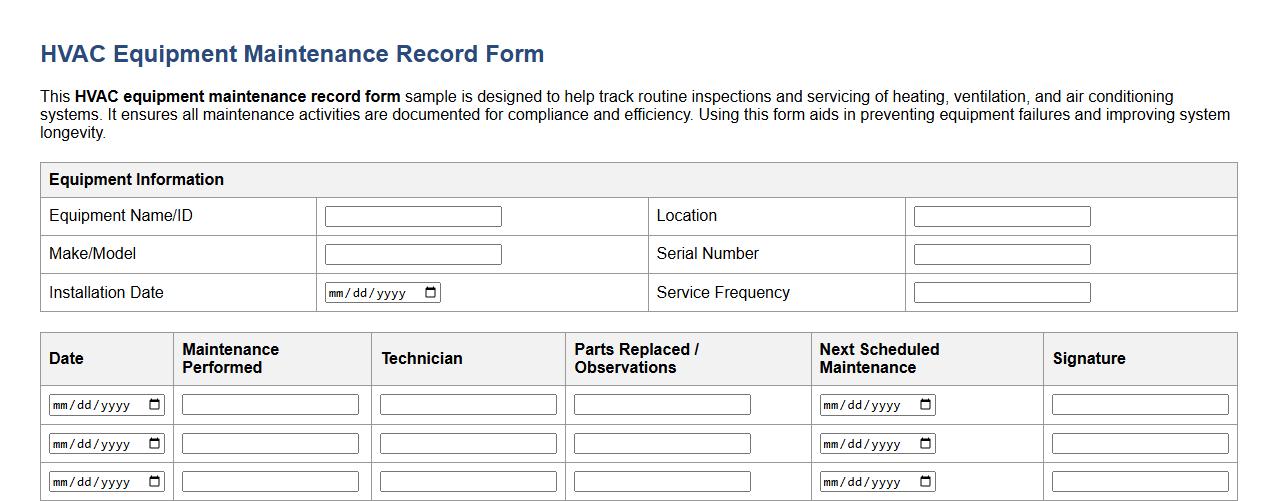

HVAC equipment maintenance record form sample

This HVAC equipment maintenance record form sample is designed to help track routine inspections and servicing of heating, ventilation, and air conditioning systems. It ensures all maintenance activities are documented for compliance and efficiency. Using this form aids in preventing equipment failures and improving system longevity.

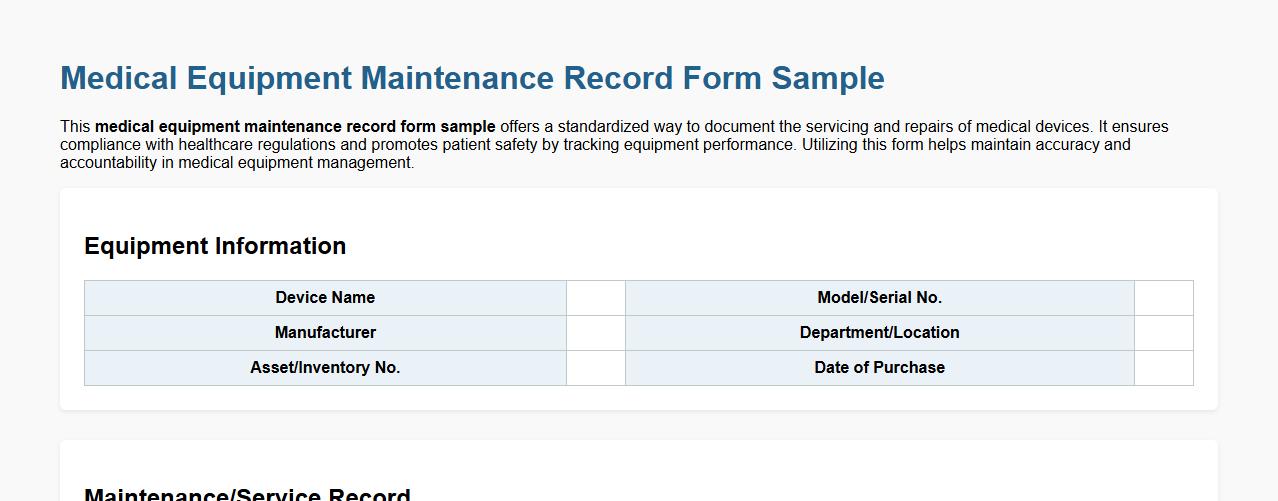

Medical equipment maintenance record form sample

This medical equipment maintenance record form sample offers a standardized way to document the servicing and repairs of medical devices. It ensures compliance with healthcare regulations and promotes patient safety by tracking equipment performance. Utilizing this form helps maintain accuracy and accountability in medical equipment management.

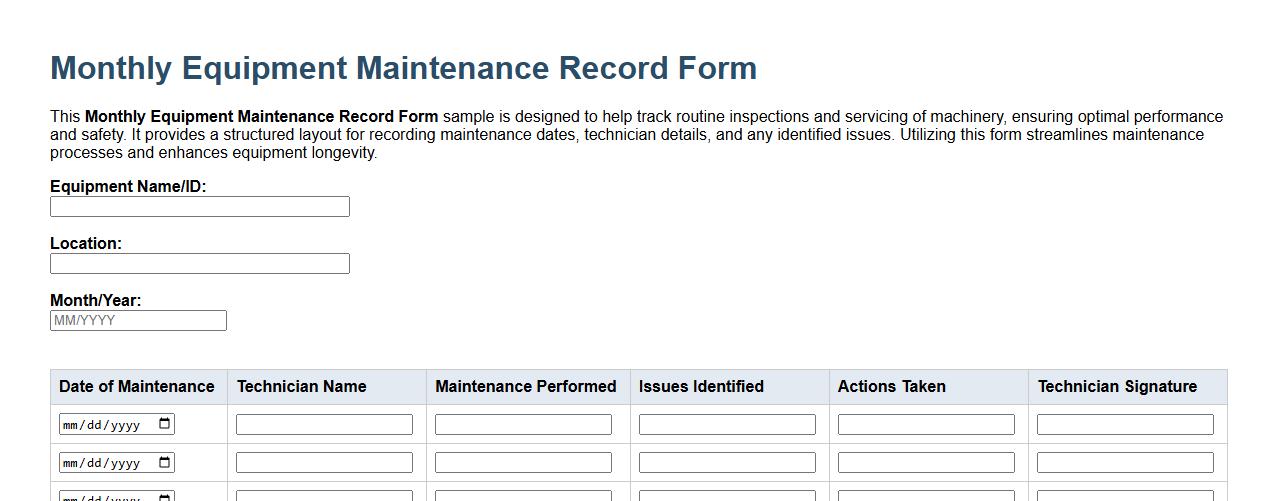

Monthly equipment maintenance record form sample

This Monthly Equipment Maintenance Record Form sample is designed to help track routine inspections and servicing of machinery, ensuring optimal performance and safety. It provides a structured layout for recording maintenance dates, technician details, and any identified issues. Utilizing this form streamlines maintenance processes and enhances equipment longevity.

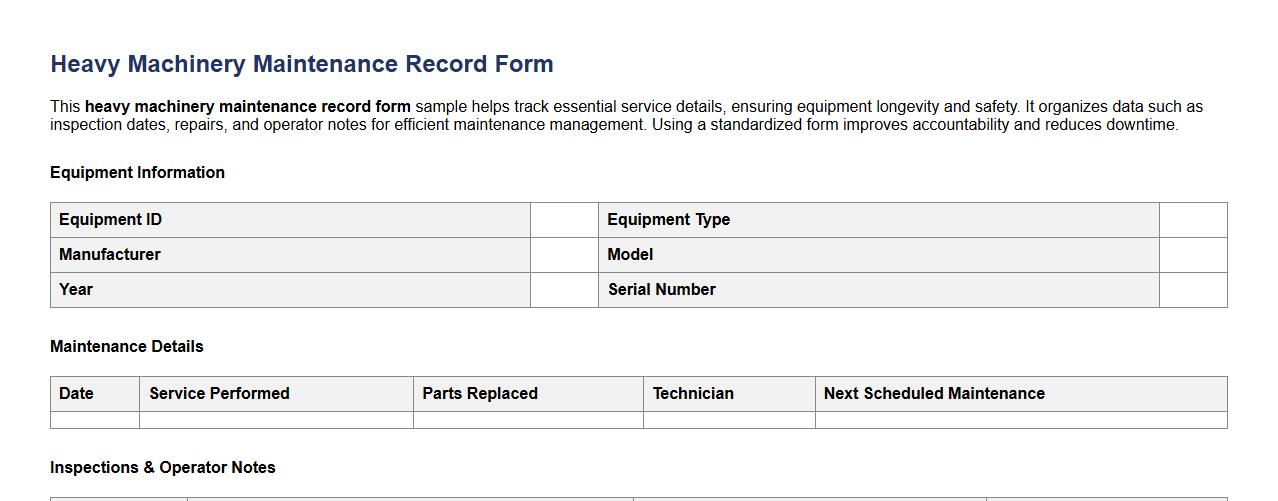

Heavy machinery maintenance record form sample

This heavy machinery maintenance record form sample helps track essential service details, ensuring equipment longevity and safety. It organizes data such as inspection dates, repairs, and operator notes for efficient maintenance management. Using a standardized form improves accountability and reduces downtime.

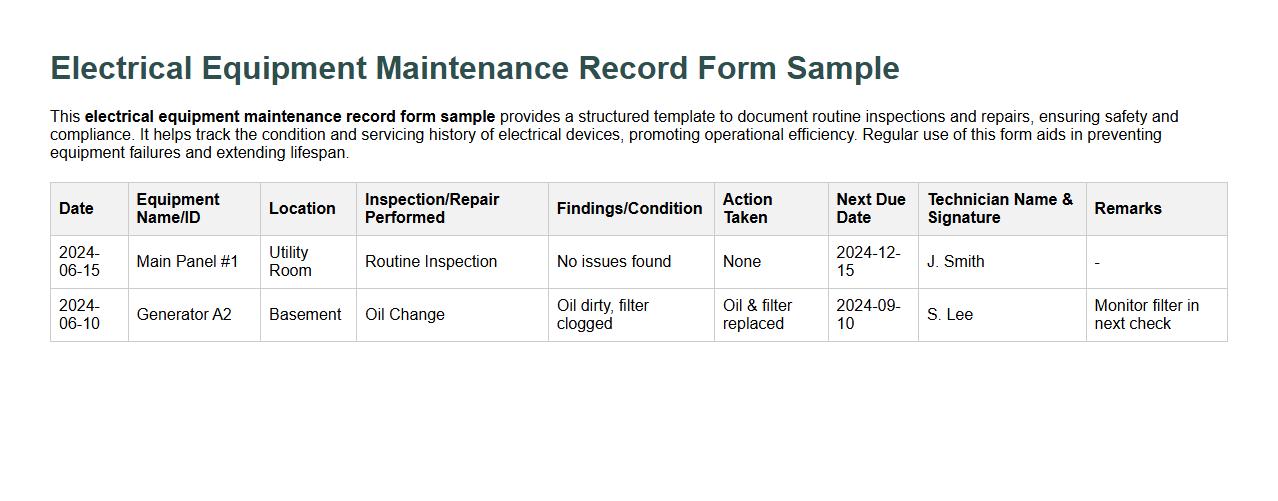

Electrical equipment maintenance record form sample

This electrical equipment maintenance record form sample provides a structured template to document routine inspections and repairs, ensuring safety and compliance. It helps track the condition and servicing history of electrical devices, promoting operational efficiency. Regular use of this form aids in preventing equipment failures and extending lifespan.

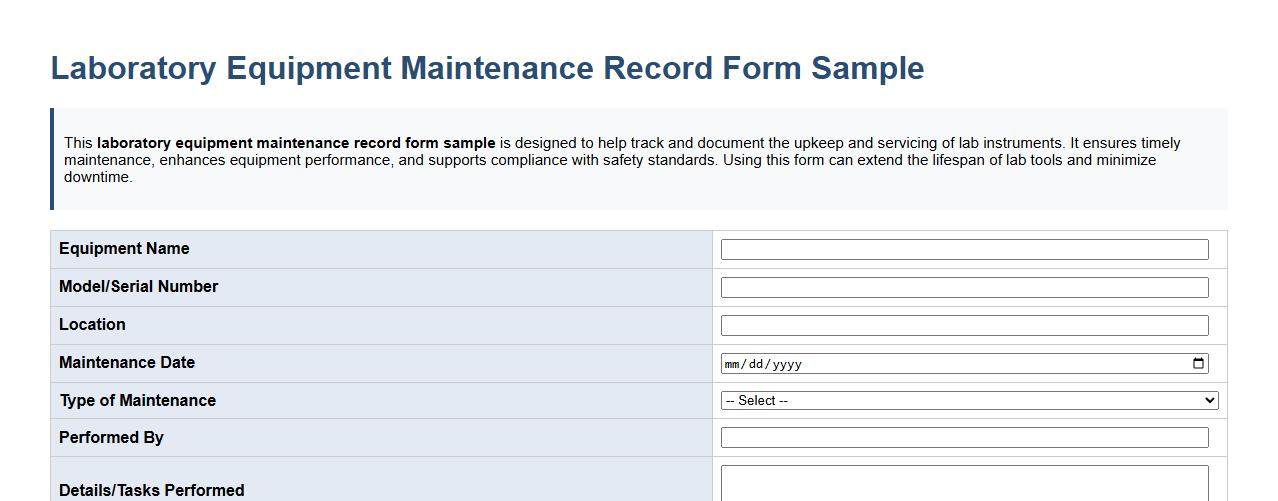

Laboratory equipment maintenance record form sample

This laboratory equipment maintenance record form sample is designed to help track and document the upkeep and servicing of lab instruments. It ensures timely maintenance, enhances equipment performance, and supports compliance with safety standards. Using this form can extend the lifespan of lab tools and minimize downtime.

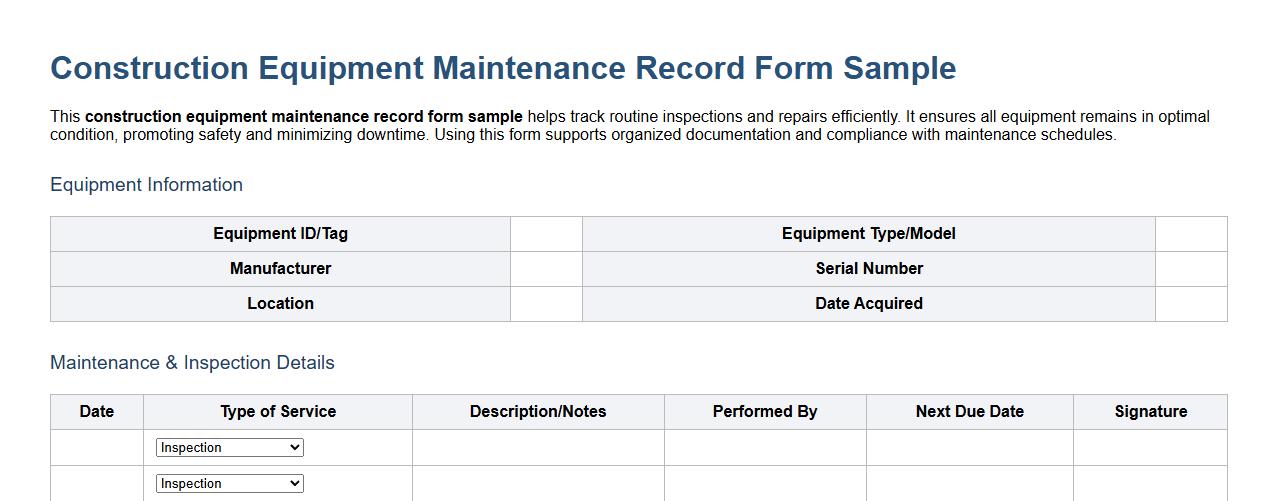

Construction equipment maintenance record form sample

This construction equipment maintenance record form sample helps track routine inspections and repairs efficiently. It ensures all equipment remains in optimal condition, promoting safety and minimizing downtime. Using this form supports organized documentation and compliance with maintenance schedules.

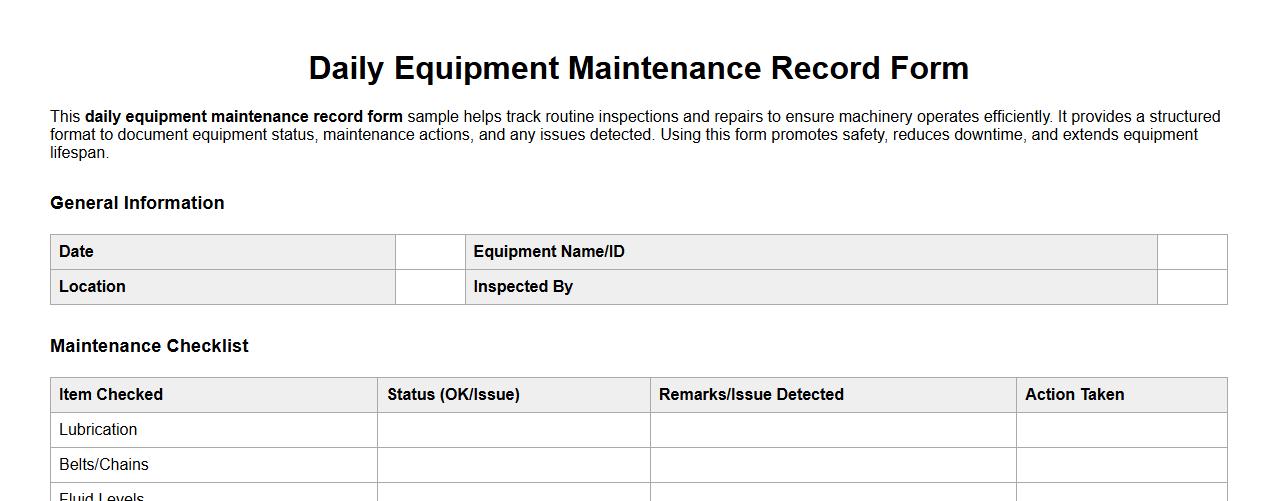

Daily equipment maintenance record form sample

This daily equipment maintenance record form sample helps track routine inspections and repairs to ensure machinery operates efficiently. It provides a structured format to document equipment status, maintenance actions, and any issues detected. Using this form promotes safety, reduces downtime, and extends equipment lifespan.

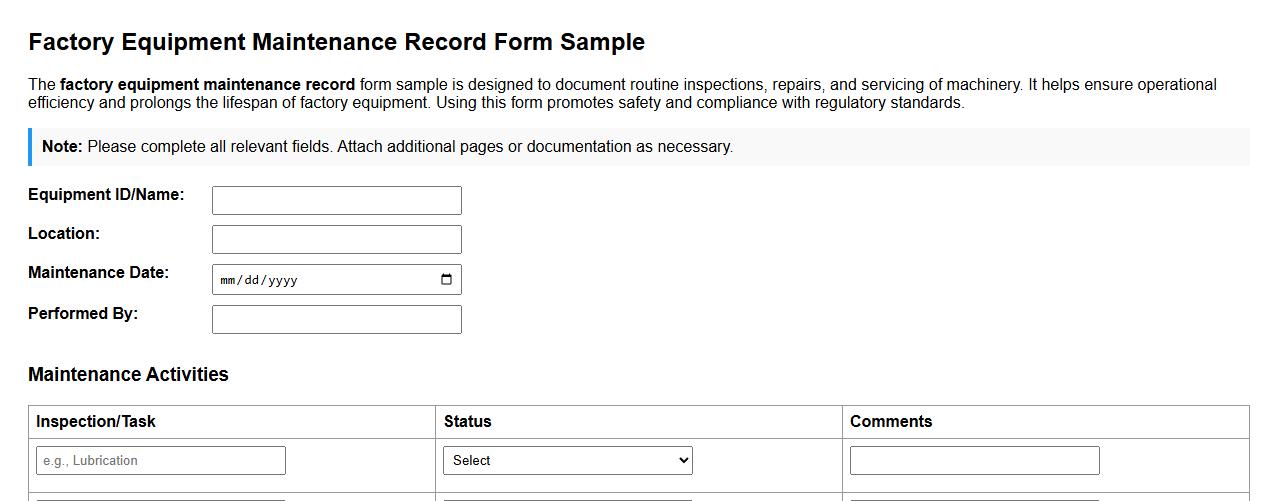

Factory equipment maintenance record form sample

The factory equipment maintenance record form sample is designed to document routine inspections, repairs, and servicing of machinery. It helps ensure operational efficiency and prolongs the lifespan of factory equipment. Using this form promotes safety and compliance with regulatory standards.

What specific intervals are documented for scheduled equipment inspections in the form?

The form specifies regular inspection intervals such as daily, weekly, and monthly checks to ensure consistent equipment maintenance. These intervals are strategically scheduled to prevent equipment downtime and extend operational life. Clear documentation of these inspection frequencies helps maintain accountability and timely intervention.

Which fields capture the technician's certification or identification details?

The form includes designated fields for technician certification numbers and personal identification details like name and employee ID. These fields verify that only qualified personnel perform the inspections and repairs. Capturing this information enhances traceability and compliance with safety standards.

How does the form record equipment serial numbers or unique identifiers?

The form features specific input boxes to record the equipment serial number or unique identifier prominently. This ensures precise identification of the inspected asset without confusion. Accurate recording facilitates tracking the equipment's maintenance history and warranty status.

What section logs the replacement of worn or defective parts?

There is a dedicated maintenance section for logging the replacement of worn or defective parts, including part description and installation date. This section helps monitor parts lifecycle and schedules timely replacements. Proper documentation supports inventory management and operational reliability.

Is there a dedicated space for supervisor approval or verification signatures?

The form includes a supervisor approval section where signatures and date of verification are required. This step ensures that the inspection and any maintenance work meet company standards. Supervisor sign-off adds an essential layer of quality control and accountability.