A Equipment Maintenance Checklist ensures systematic inspection and servicing of machinery to prevent breakdowns and extend operational life. It includes detailed steps for routine tasks such as lubrication, cleaning, and parts replacement. Regular use of this checklist enhances safety, efficiency, and compliance with industry standards.

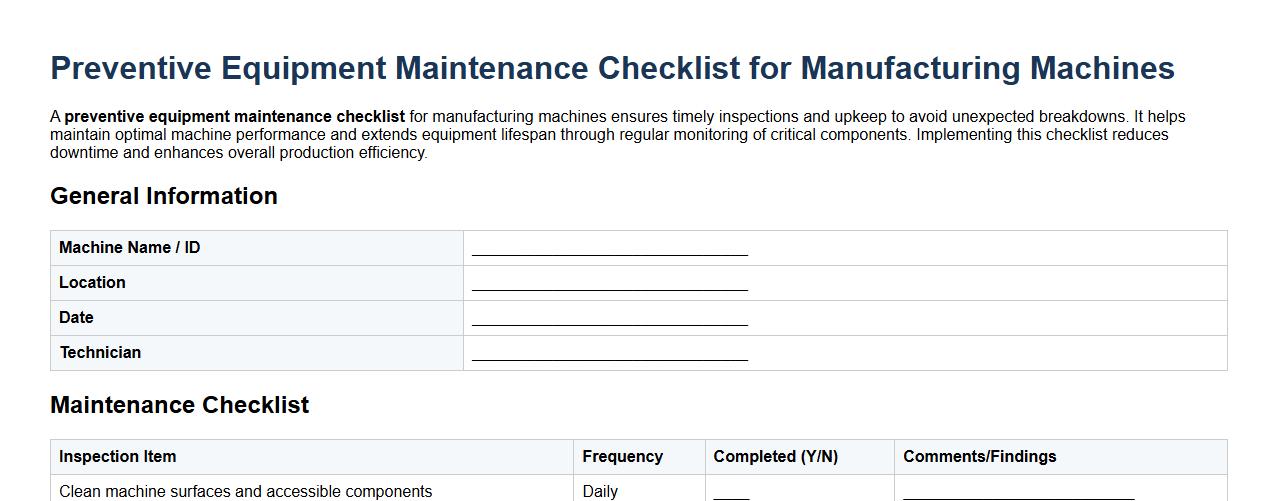

Preventive equipment maintenance checklist for manufacturing machines

A preventive equipment maintenance checklist for manufacturing machines ensures timely inspections and upkeep to avoid unexpected breakdowns. It helps maintain optimal machine performance and extends equipment lifespan through regular monitoring of critical components. Implementing this checklist reduces downtime and enhances overall production efficiency.

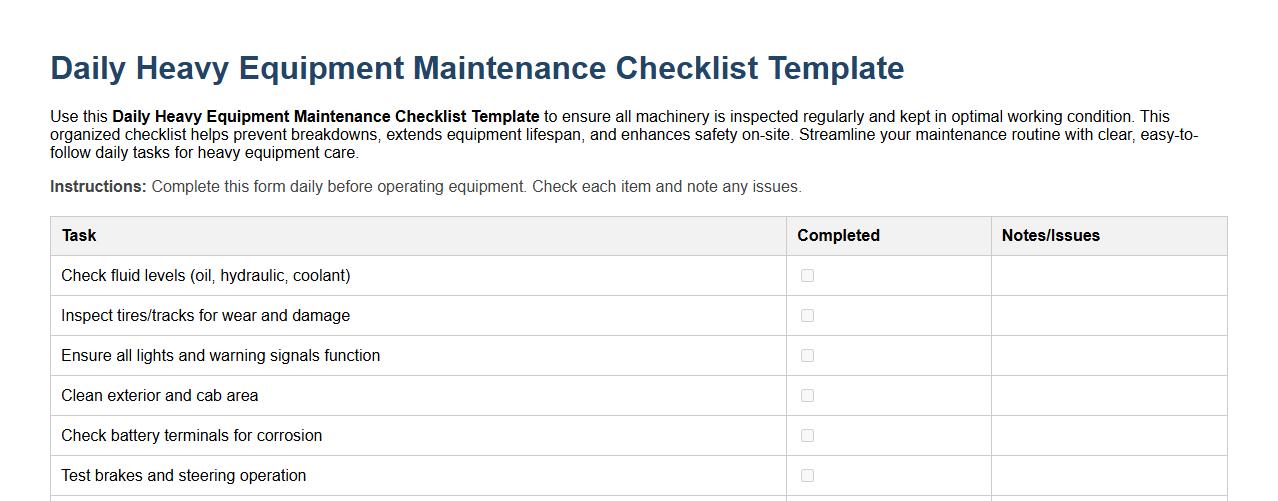

Daily heavy equipment maintenance checklist template

Use this Daily Heavy Equipment Maintenance Checklist Template to ensure all machinery is inspected regularly and kept in optimal working condition. This organized checklist helps prevent breakdowns, extends equipment lifespan, and enhances safety on-site. Streamline your maintenance routine with clear, easy-to-follow daily tasks for heavy equipment care.

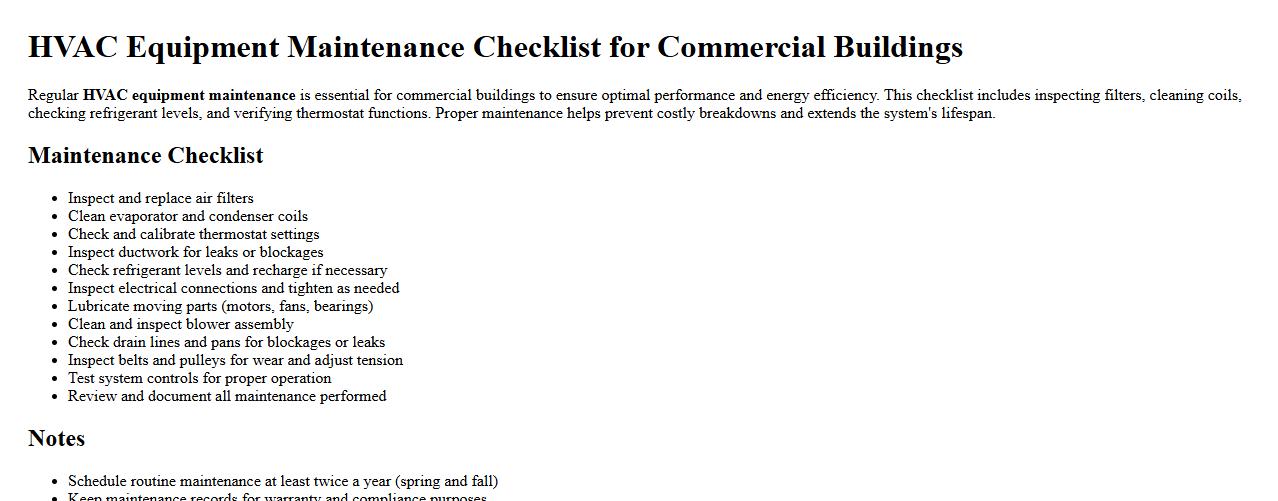

HVAC equipment maintenance checklist for commercial buildings

Regular HVAC equipment maintenance is essential for commercial buildings to ensure optimal performance and energy efficiency. This checklist includes inspecting filters, cleaning coils, checking refrigerant levels, and verifying thermostat functions. Proper maintenance helps prevent costly breakdowns and extends the system's lifespan.

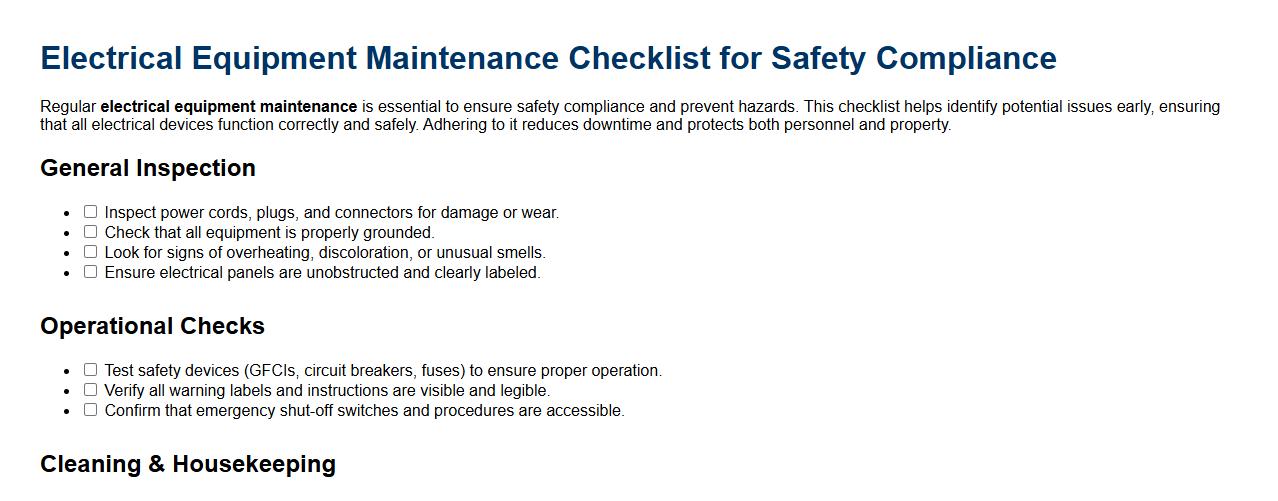

Electrical equipment maintenance checklist for safety compliance

Regular electrical equipment maintenance is essential to ensure safety compliance and prevent hazards. This checklist helps identify potential issues early, ensuring that all electrical devices function correctly and safely. Adhering to it reduces downtime and protects both personnel and property.

Medical equipment maintenance checklist for hospitals

A medical equipment maintenance checklist for hospitals ensures the safety, reliability, and proper functioning of critical devices. Regular inspections and servicing help prevent malfunctions and extend the lifespan of essential medical tools. Implementing a systematic checklist supports compliance with healthcare standards and enhances patient care quality.

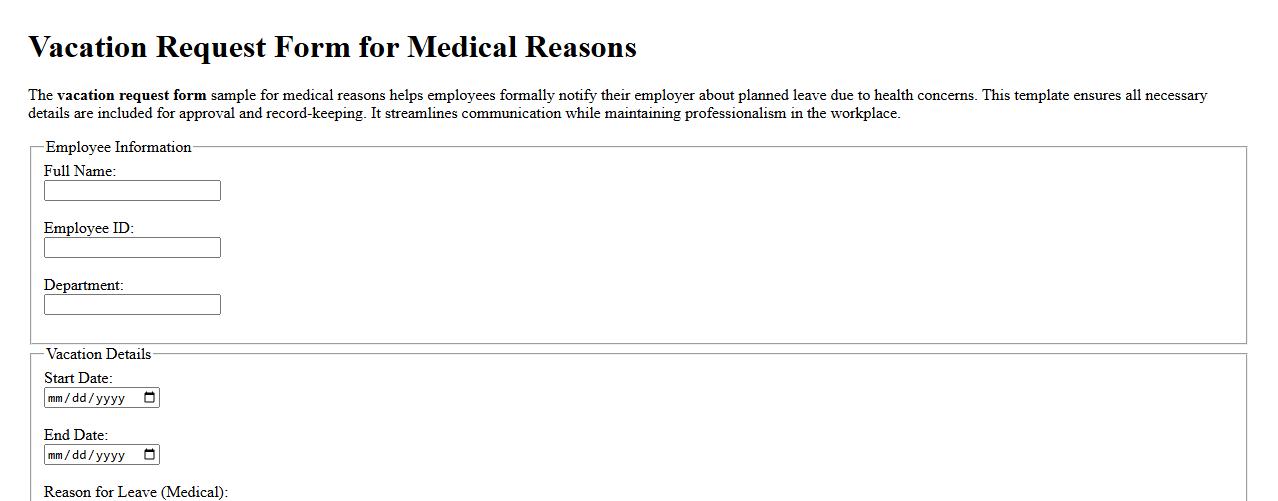

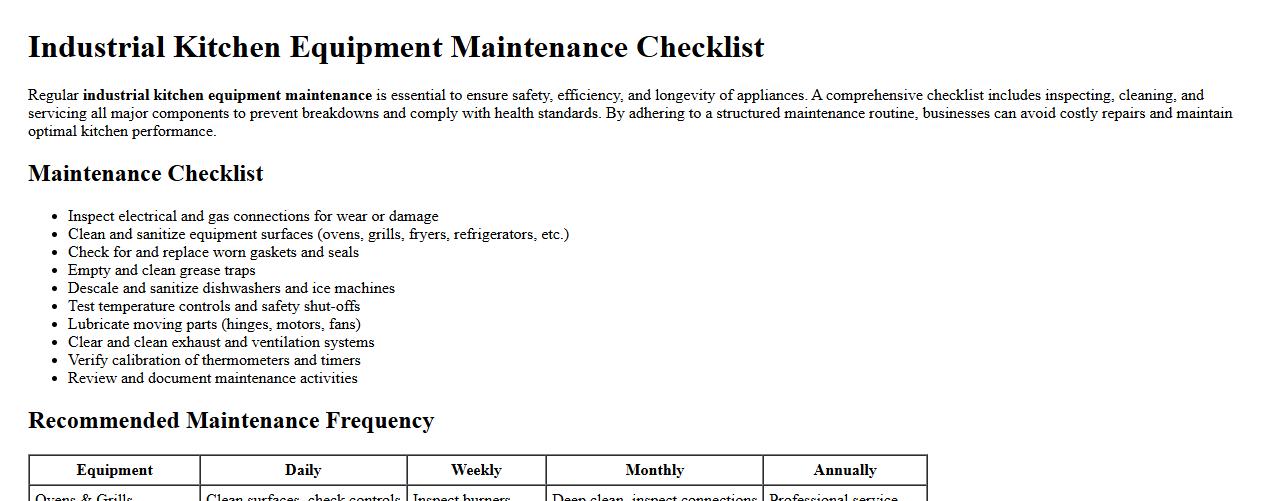

Industrial kitchen equipment maintenance checklist

Regular industrial kitchen equipment maintenance is essential to ensure safety, efficiency, and longevity of appliances. A comprehensive checklist includes inspecting, cleaning, and servicing all major components to prevent breakdowns and comply with health standards. By adhering to a structured maintenance routine, businesses can avoid costly repairs and maintain optimal kitchen performance.

Construction site equipment maintenance checklist pdf

Ensure safety and efficiency with our comprehensive construction site equipment maintenance checklist PDF. This essential guide helps track routine inspections and upkeep tasks to prevent equipment failures. Download the checklist to maintain optimal performance and extend the lifespan of your machinery.

Monthly automotive equipment maintenance checklist

Ensure your vehicle's optimal performance with our monthly automotive equipment maintenance checklist. Regular inspections and timely upkeep help prevent costly repairs and extend the lifespan of your equipment. Stay safe and efficient on the road by following these essential monthly maintenance tasks.

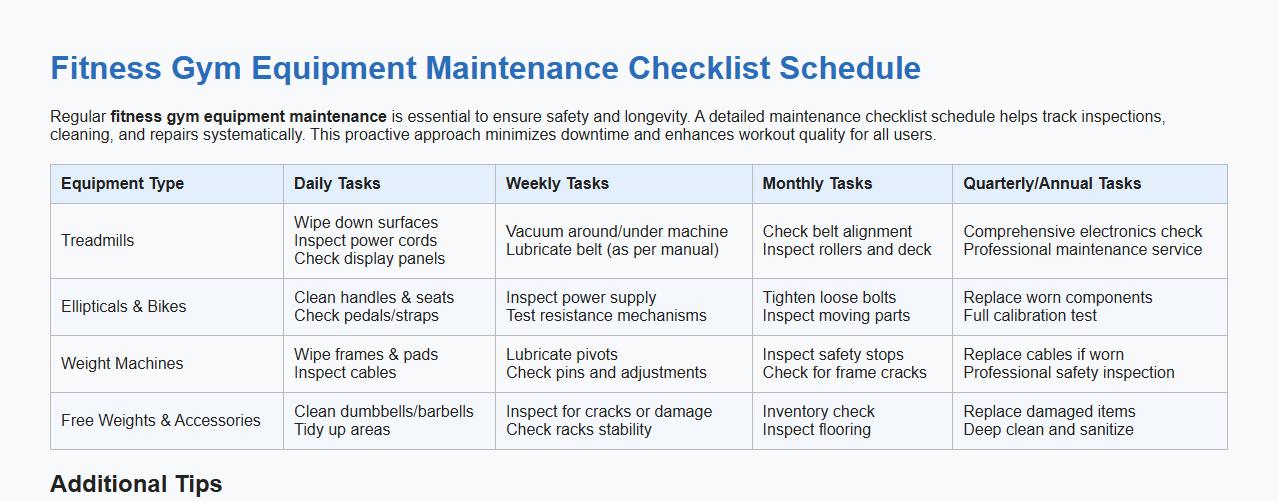

Fitness gym equipment maintenance checklist schedule

Regular fitness gym equipment maintenance is essential to ensure safety and longevity. A detailed maintenance checklist schedule helps track inspections, cleaning, and repairs systematically. This proactive approach minimizes downtime and enhances workout quality for all users.

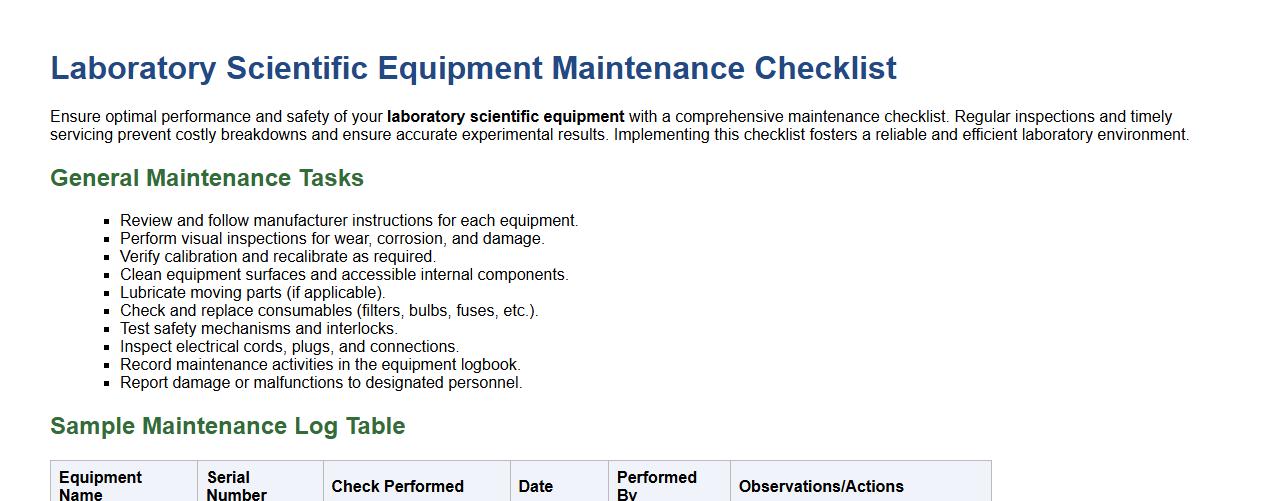

Laboratory scientific equipment maintenance checklist

Ensure optimal performance and safety of your laboratory scientific equipment with a comprehensive maintenance checklist. Regular inspections and timely servicing prevent costly breakdowns and ensure accurate experimental results. Implementing this checklist fosters a reliable and efficient laboratory environment.

What regulatory standards must the Equipment Maintenance Checklist document meet?

The Equipment Maintenance Checklist must comply with industry-specific regulations such as OSHA, ISO, and FDA standards where applicable. It should ensure all safety, inspection, and maintenance activities are documented in accordance with local and international regulatory requirements. Proper adherence to these standards guarantees legal compliance and enhances equipment reliability and safety.

How should critical failure points be documented in the checklist?

Critical failure points should be clearly identified and highlighted within the checklist using distinctive labels or color coding to draw attention. Each identified point must include a detailed description, potential impact, and recommended preventive actions. This structured documentation helps in prioritizing maintenance tasks and mitigating risks effectively.

What intervals are optimal for updating maintenance procedures in the checklist?

Maintenance procedures in the checklist should be reviewed and updated at least annually or after any significant equipment change. More frequent updates may be necessary based on equipment usage intensity or after an incident occurs. Regular updates ensure that procedures stay current with technological advancements and operational requirements.

How can digital signatures be integrated into the checklist workflow?

Digital signatures can be integrated via secure electronic signature platforms such as DocuSign or Adobe Sign to authenticate the checklist records. This integration ensures data integrity, accountability, and compliance with legal standards for electronic documentation. It also streamlines the approval process and enhances traceability of maintenance activities.

What is the best format for recording calibration data within the checklist?

Calibration data should be recorded in a standardized tabular format including columns for date, equipment ID, calibration results, and technician details. This format facilitates easy comparison, tracking, and verification of calibration history. Consistent data formatting enhances transparency and simplifies regulatory audits.