A Maintenance Log Form Sample helps track routine inspections, repairs, and equipment servicing efficiently. This form records essential details such as dates, tasks performed, and personnel responsible, ensuring accurate maintenance history. Using a well-structured log improves asset management and reduces downtime by facilitating timely interventions.

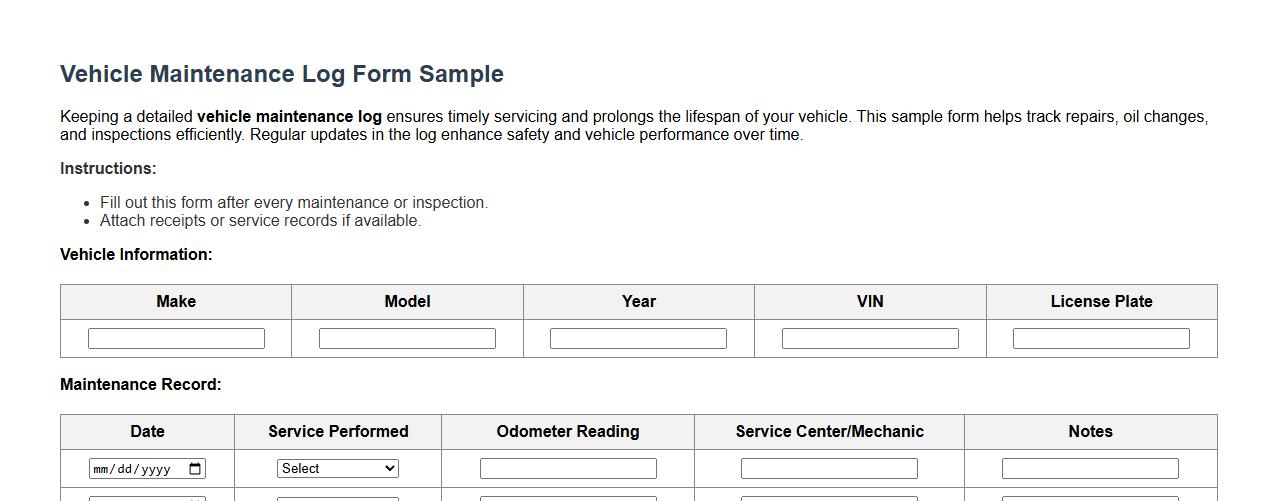

Vehicle maintenance log form sample

Keeping a detailed vehicle maintenance log ensures timely servicing and prolongs the lifespan of your vehicle. This sample form helps track repairs, oil changes, and inspections efficiently. Regular updates in the log enhance safety and vehicle performance over time.

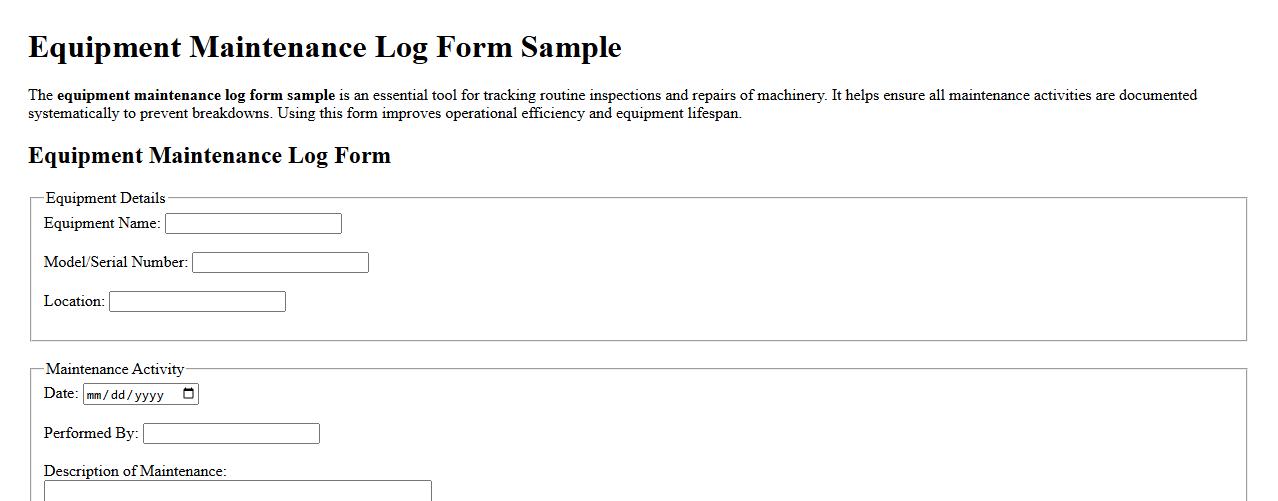

Equipment maintenance log form sample

The equipment maintenance log form sample is an essential tool for tracking routine inspections and repairs of machinery. It helps ensure all maintenance activities are documented systematically to prevent breakdowns. Using this form improves operational efficiency and equipment lifespan.

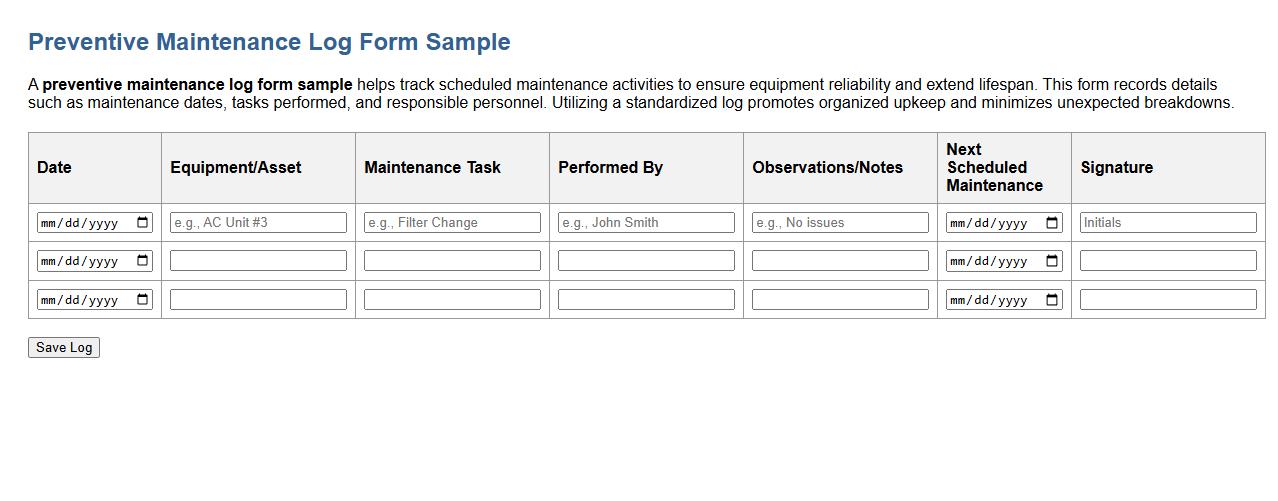

Preventive maintenance log form sample

A preventive maintenance log form sample helps track scheduled maintenance activities to ensure equipment reliability and extend lifespan. This form records details such as maintenance dates, tasks performed, and responsible personnel. Utilizing a standardized log promotes organized upkeep and minimizes unexpected breakdowns.

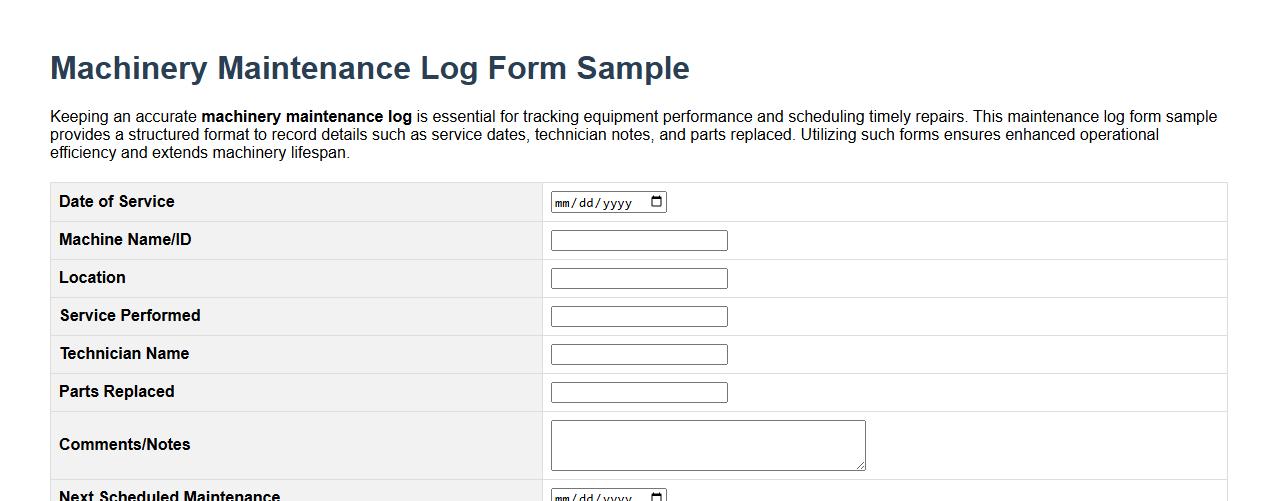

Machinery maintenance log form sample

Keeping an accurate machinery maintenance log is essential for tracking equipment performance and scheduling timely repairs. This maintenance log form sample provides a structured format to record details such as service dates, technician notes, and parts replaced. Utilizing such forms ensures enhanced operational efficiency and extends machinery lifespan.

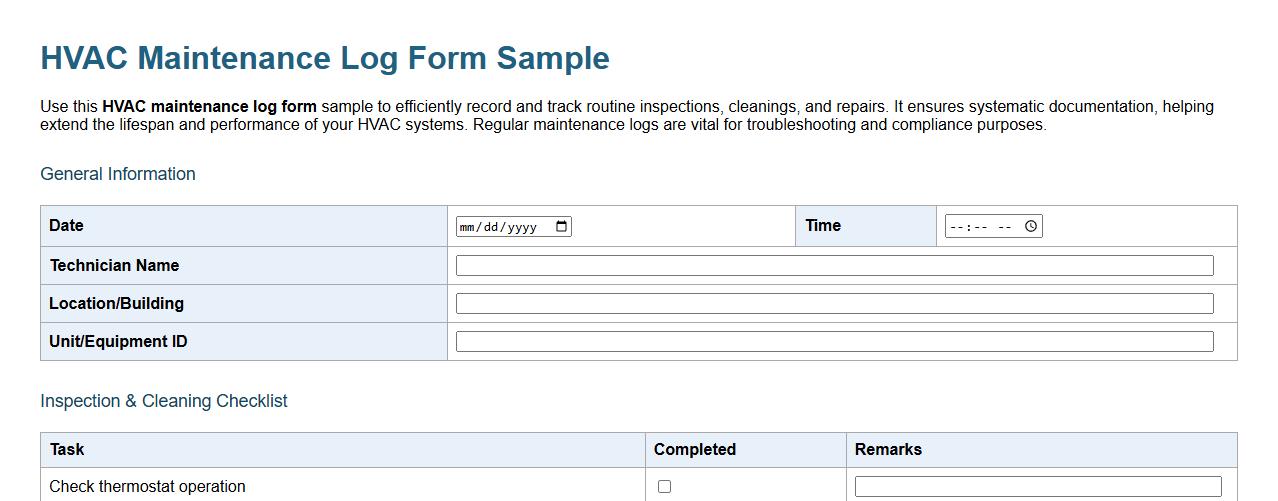

HVAC maintenance log form sample

Use this HVAC maintenance log form sample to efficiently record and track routine inspections, cleanings, and repairs. It ensures systematic documentation, helping extend the lifespan and performance of your HVAC systems. Regular maintenance logs are vital for troubleshooting and compliance purposes.

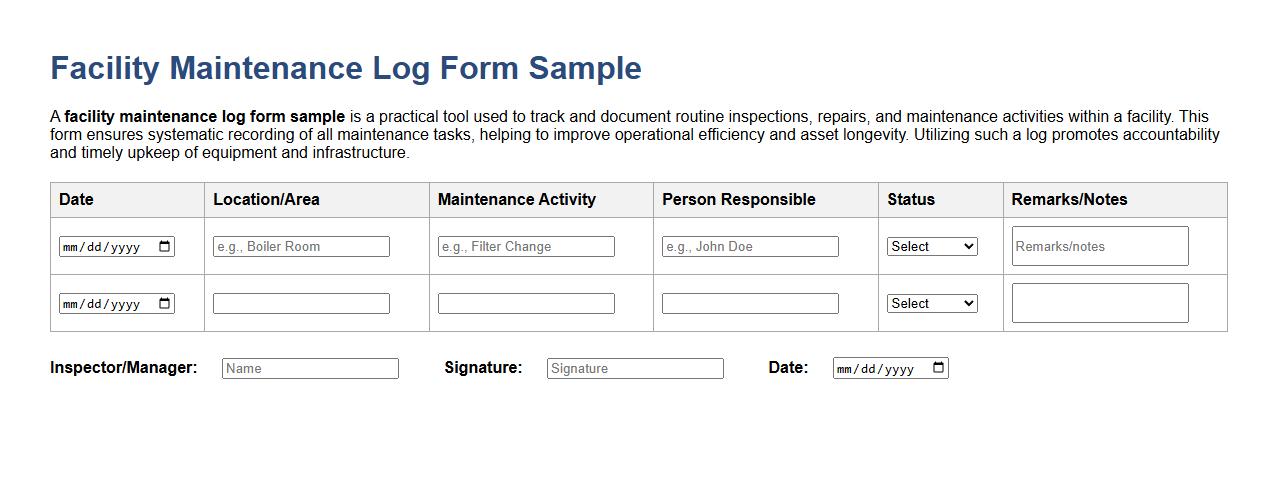

Facility maintenance log form sample

A facility maintenance log form sample is a practical tool used to track and document routine inspections, repairs, and maintenance activities within a facility. This form ensures systematic recording of all maintenance tasks, helping to improve operational efficiency and asset longevity. Utilizing such a log promotes accountability and timely upkeep of equipment and infrastructure.

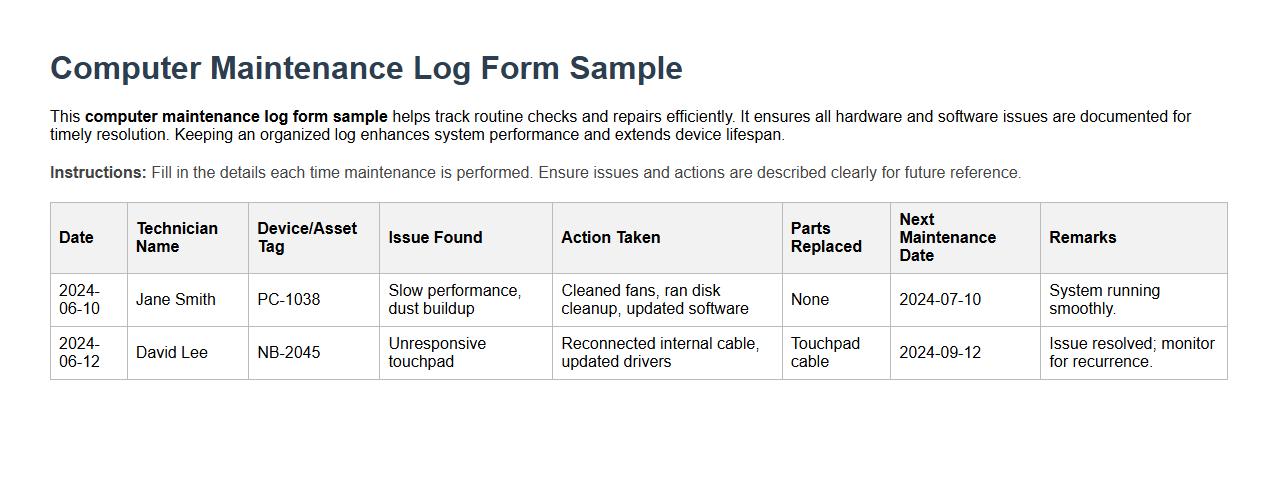

Computer maintenance log form sample

This computer maintenance log form sample helps track routine checks and repairs efficiently. It ensures all hardware and software issues are documented for timely resolution. Keeping an organized log enhances system performance and extends device lifespan.

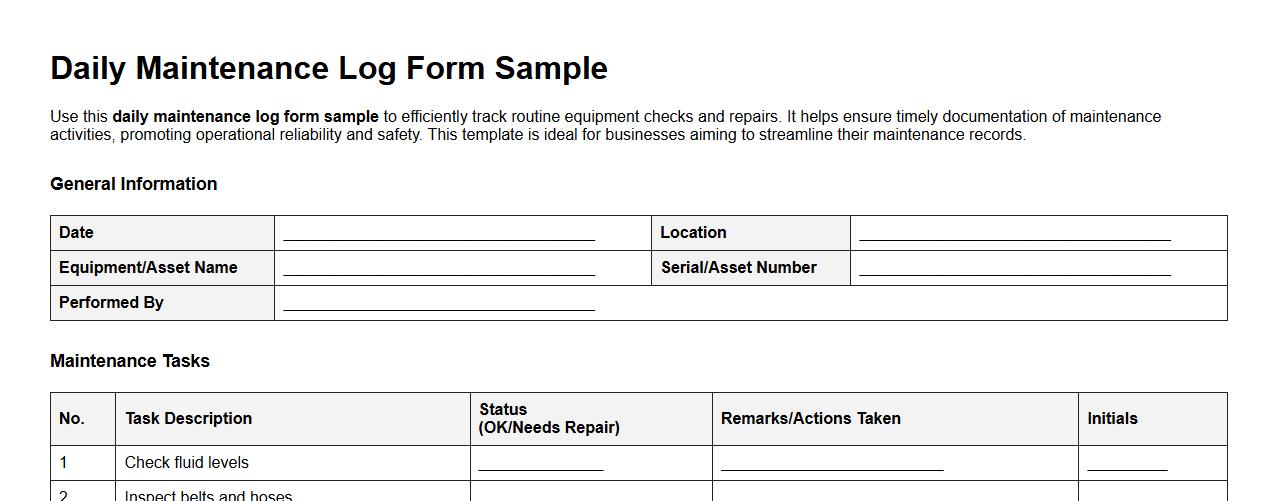

Daily maintenance log form sample

Use this daily maintenance log form sample to efficiently track routine equipment checks and repairs. It helps ensure timely documentation of maintenance activities, promoting operational reliability and safety. This template is ideal for businesses aiming to streamline their maintenance records.

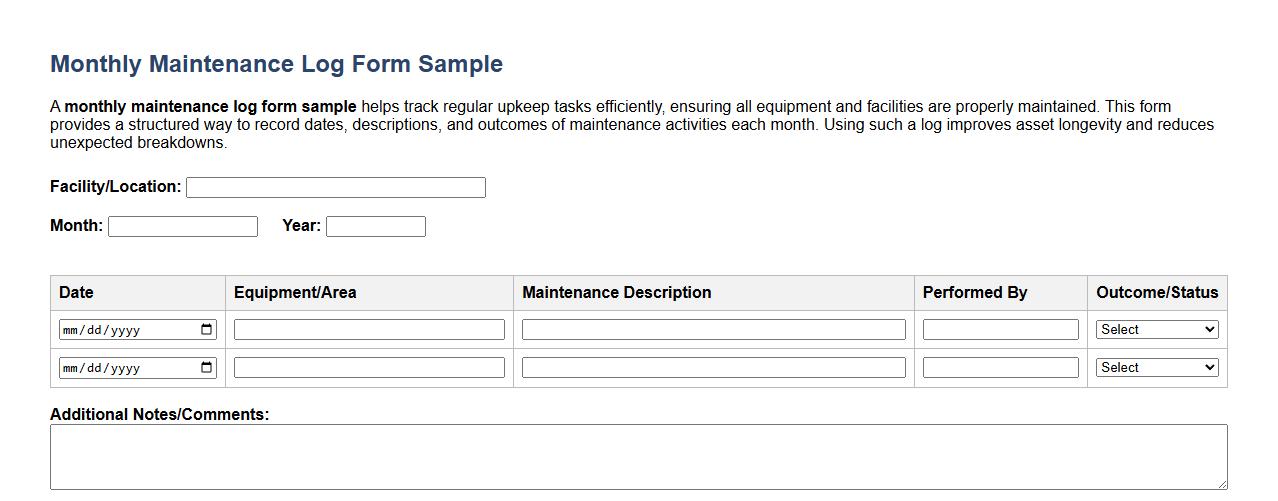

Monthly maintenance log form sample

A monthly maintenance log form sample helps track regular upkeep tasks efficiently, ensuring all equipment and facilities are properly maintained. This form provides a structured way to record dates, descriptions, and outcomes of maintenance activities each month. Using such a log improves asset longevity and reduces unexpected breakdowns.

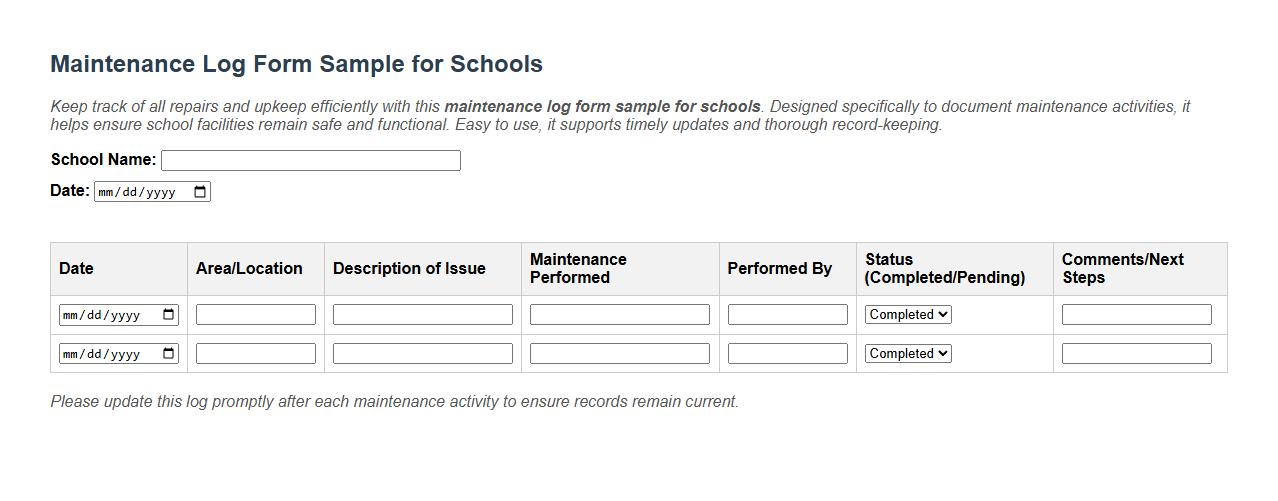

Maintenance log form sample for schools

Keep track of all repairs and upkeep efficiently with this maintenance log form sample for schools. Designed specifically to document maintenance activities, it helps ensure school facilities remain safe and functional. Easy to use, it supports timely updates and thorough record-keeping.

What fields are essential for tracking equipment serviced in the Maintenance Log Form?

The essential fields in a Maintenance Log Form include equipment identification, service date, and detailed description of the maintenance performed. Capturing the technician's name and the parts used during servicing ensures accountability and traceability. Additionally, recording the next scheduled maintenance date helps in proactive equipment management.

How often should entries be updated in the Maintenance Log Form for compliance?

Entries in the Maintenance Log Form should be updated immediately after each maintenance event to ensure accuracy and compliance. Regular updates prevent missed tasks and help adhere to industry regulations and internal standards. Maintaining timely records supports audits and enhances equipment reliability.

What digital tools can integrate with a Maintenance Log Form for real-time monitoring?

Digital tools like Computerized Maintenance Management Systems (CMMS) and IoT-enabled sensors can integrate seamlessly with Maintenance Log Forms. These technologies facilitate real-time data capture and provide automated alerts for upcoming maintenance. Integration boosts efficiency by enabling continuous monitoring and instant reporting.

Which regulatory standards impact the design of a Maintenance Log Form?

Regulatory standards such as ISO 55000 for asset management and OSHA requirements influence Maintenance Log Form design. Compliance with these standards ensures proper documentation and safety adherence. Incorporating regulatory guidelines helps in meeting legal and operational obligations.

How can historical Maintenance Log Form data be leveraged for predictive maintenance?

Historical data from Maintenance Log Forms provides valuable insights into equipment performance trends and failure patterns. Analyzing this data enables predictive maintenance strategies to anticipate issues before they occur. Leveraging past records improves resource allocation and minimizes unexpected downtime.