A Production Order Form Sample is a template used to organize and document the details of a manufacturing process, including product specifications, quantity, and deadlines. This form ensures clear communication between departments, streamlining the production workflow and reducing errors. Utilizing a well-designed Production Order Form Sample improves efficiency and accountability in manufacturing operations.

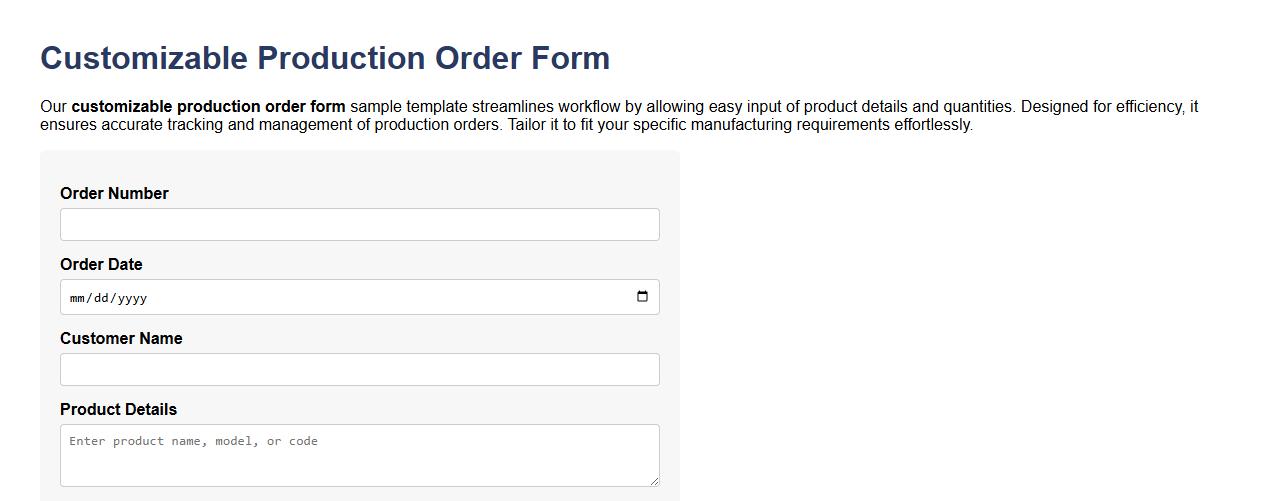

Customizable production order form sample template

Our customizable production order form sample template streamlines workflow by allowing easy input of product details and quantities. Designed for efficiency, it ensures accurate tracking and management of production orders. Tailor it to fit your specific manufacturing requirements effortlessly.

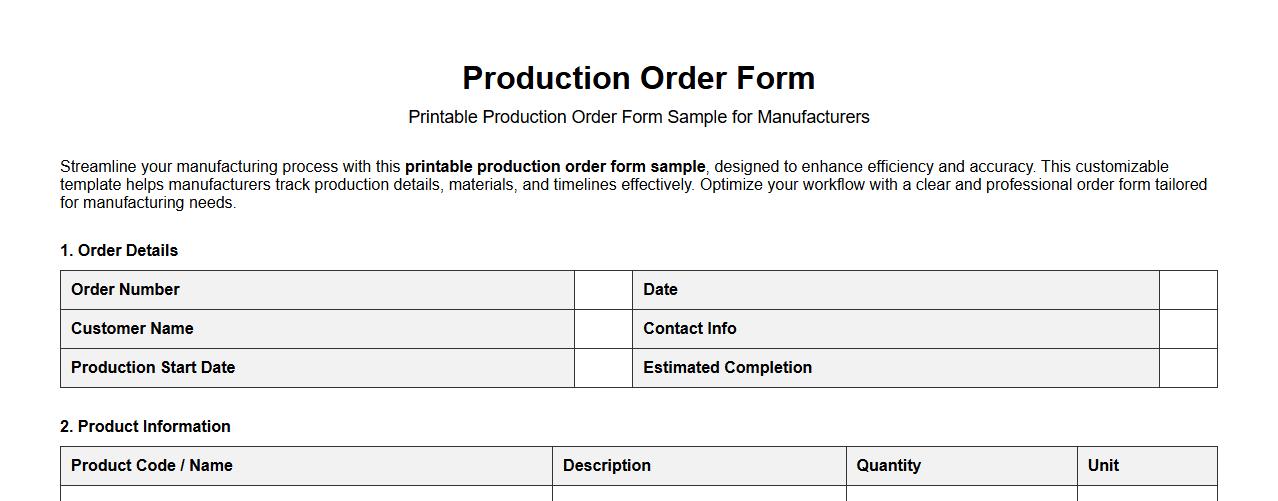

Printable production order form sample for manufacturers

Streamline your manufacturing process with this printable production order form sample, designed to enhance efficiency and accuracy. This customizable template helps manufacturers track production details, materials, and timelines effectively. Optimize your workflow with a clear and professional order form tailored for manufacturing needs.

Pdf production order form sample with item details

This PDF production order form sample provides a clear layout for listing item details, ensuring accurate and efficient order processing. It is designed to streamline communication between departments by capturing essential product specifications and quantities. Using this form helps maintain consistency and reduces errors in production workflows.

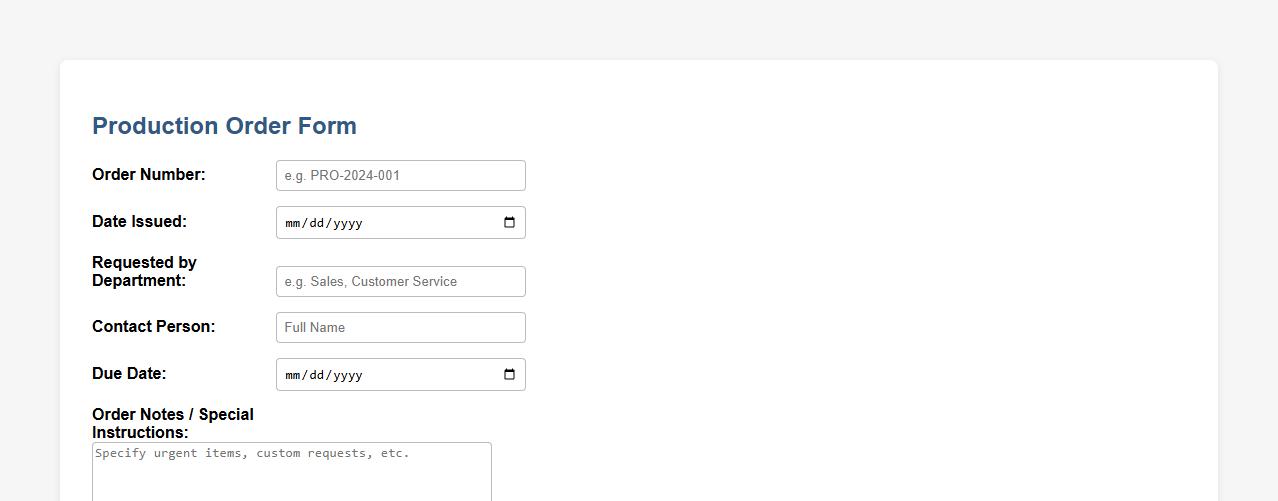

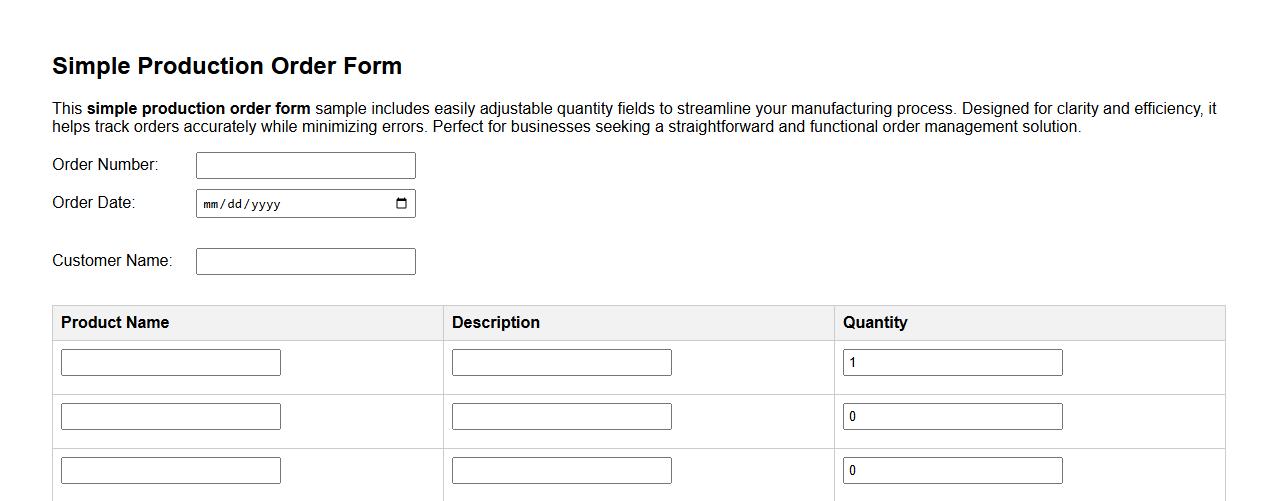

Simple production order form sample with quantity fields

This simple production order form sample includes easily adjustable quantity fields to streamline your manufacturing process. Designed for clarity and efficiency, it helps track orders accurately while minimizing errors. Perfect for businesses seeking a straightforward and functional order management solution.

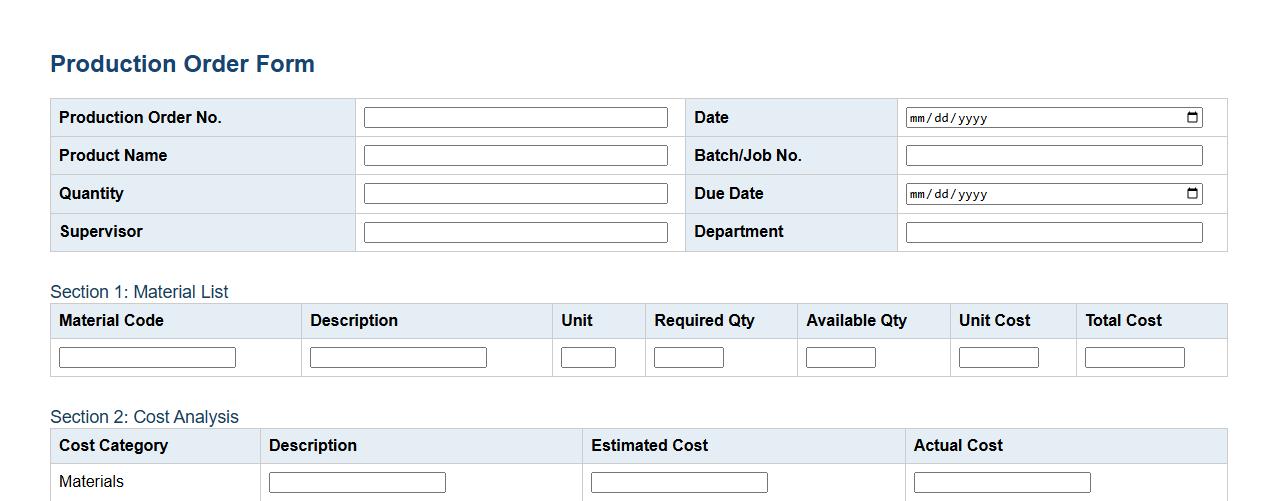

Production order form sample with cost and material sections

This production order form sample includes detailed sections for cost and material, ensuring accurate tracking and budgeting throughout the manufacturing process. The form is designed to optimize workflow by clearly listing required materials alongside associated expenses. It serves as a vital tool for managing production efficiency and resource allocation.

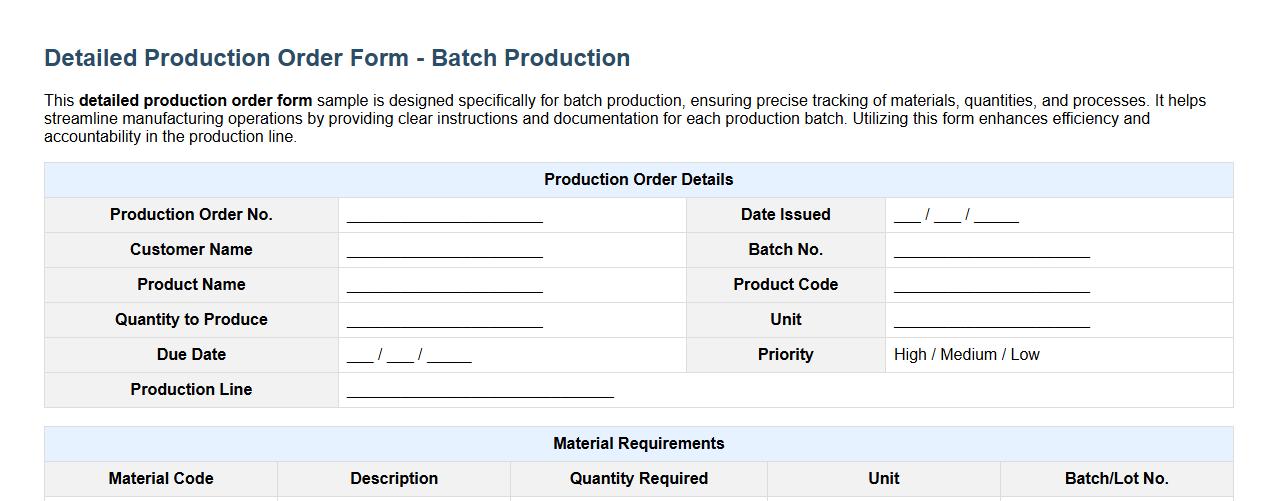

Detailed production order form sample for batch production

This detailed production order form sample is designed specifically for batch production, ensuring precise tracking of materials, quantities, and processes. It helps streamline manufacturing operations by providing clear instructions and documentation for each production batch. Utilizing this form enhances efficiency and accountability in the production line.

Sample production order form with approval signature lines

This sample production order form streamlines the manufacturing process by clearly detailing item specifications and quantities. It includes designated approval signature lines to ensure authorized validation before proceeding. Utilizing this form enhances accountability and communication across production teams.

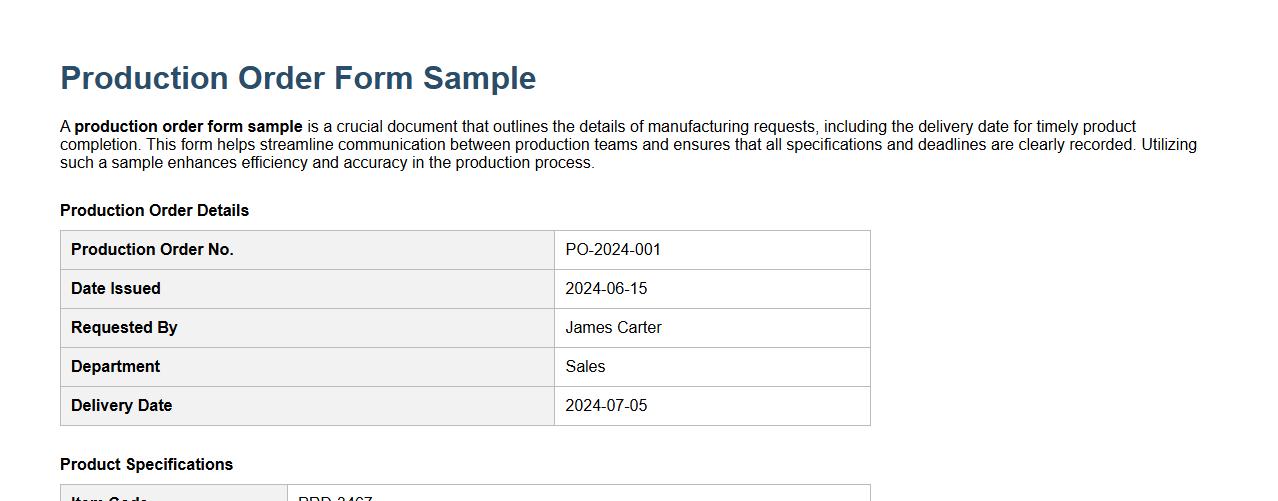

Production order form sample including delivery date

A production order form sample is a crucial document that outlines the details of manufacturing requests, including the delivery date for timely product completion. This form helps streamline communication between production teams and ensures that all specifications and deadlines are clearly recorded. Utilizing such a sample enhances efficiency and accuracy in the production process.

Production order form sample with job tracking number

A production order form sample with a job tracking number streamlines manufacturing processes by clearly documenting job details and progress. It ensures efficient communication and accurate tracking from initiation to completion. This form is essential for maintaining organization and timely delivery in production workflows.

What are the mandatory data fields required in the Production Order Form?

The Production Order Form must include essential data fields such as the product name, quantity to be produced, and scheduled production date. Additionally, it requires detailed materials list and operator information. Accurate entry of these fields ensures smooth production workflow and traceability.

How is revision history tracked within the Production Order Form?

The revision history is tracked by maintaining a version control system embedded in the Production Order Form. Each update records the date, time, and user who made the changes along with a summary of modifications. This process guarantees transparency and accountability throughout the production cycle.

Which department is responsible for authorizing deviations on the Production Order Form?

The Quality Assurance (QA) department typically holds responsibility for authorizing any deviations noted on the Production Order Form. They evaluate the impact and ensure compliance with regulatory standards before approval. This control helps maintain product quality and process consistency.

How does the Production Order Form integrate with inventory control systems?

The Production Order Form integrates seamlessly with inventory control systems through automated data synchronization. This linkage updates raw material consumption and finished goods inventory in real-time. Such integration improves accuracy in stock levels and reduces production delays.

What digital signature options are available for verifying the Production Order Form?

Digital signatures for verifying the Production Order Form include options like PKI-based certificates, biometric sign-ins, and secure e-signature platforms. These signatures ensure authenticity and legally binding approvals. Adoption of digital verification enhances security and audit readiness.